Process

Our Waterproof & Breathable Technologies

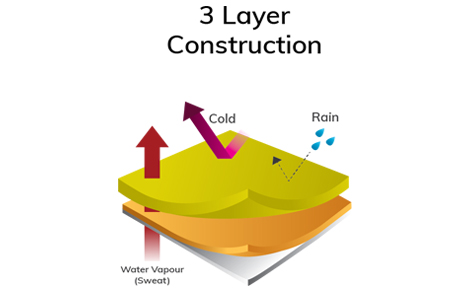

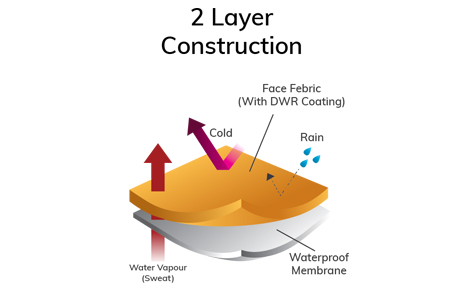

Our waterproof technologies are methods of bonding or laminating materials together. These use heat to create a bond between two materials. However, our lamination developments differ in the specific method of application of heat and adhesive. There are a lot of variables to consider during bounding or lamination processes to obtain the requested strength and appearance.

Why Lamination

Sustainable

Low MOQs

Strength

Functionality

This process provides additional functionality and versatility with fabric on one side and non-woven on the other, fabric on both sides, and many variations of fabric combinations, creating composites including foams, films, and knits. These combined composite materials will have properties and characteristics that the individual layers would not have by themselves.

Flamebounding

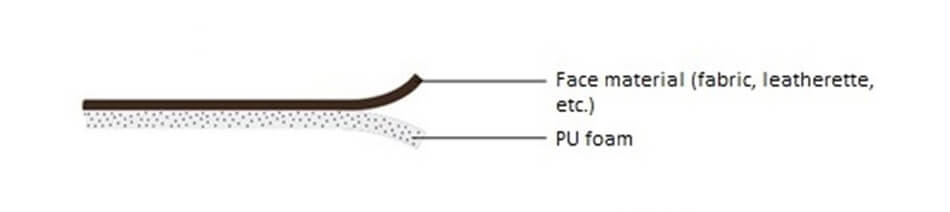

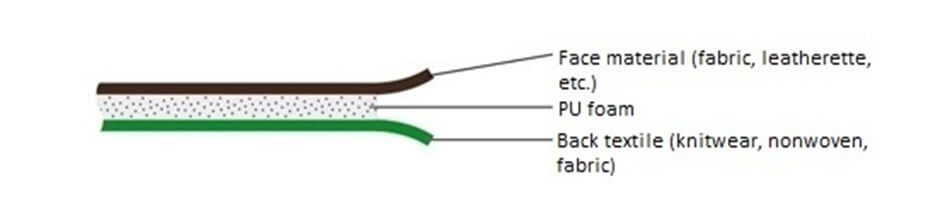

Flame lamination is a textile process used to bond two or more layers of fabric using heat and flame. In this process, a layer of foam is applied to one of the fabrics, and then the two fabrics are fed through a bounding installation that applies a controlled flame to the thermoplastic layer. The heat from the flame melts the foamlayer, causing it to bond with the other fabric. The result is a strong, durable bond between the two fabrics that is water-resistant and often used in applications such as shoe linings, sportswear, upholstery, and many more. Flame lamination is a fast and efficient process that allows for precise control of the bond strength and is often preferred over other bonding methods for its speed and accuracy.

Check: Use of foam

2 - Layers

Polarfleece / Foam

Application: Furniture

3 - Layers

Polarfleece/Foam/Textile

Application: Automotive, Furniture

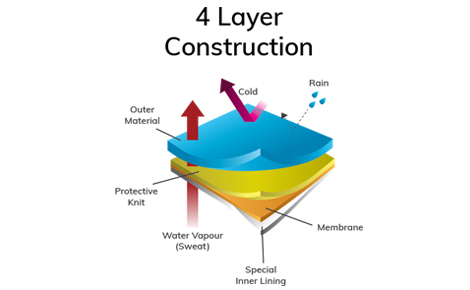

4 - Layers

Polarfleece/Foam/Mesh/Membrane

Application: Automotive, Furniture

2 - Layers

Application: Furniture

3 - Layers

Application: Automotive, Furniture

4 - Layers

Application: Automotive, Furniture

Dotlamination

Dotlamination is a process used to bond fabrics together using heat and adhesive. In this process, a thin layer of adhesive is applied to the surface of one fabric, and then a second fabric is pressed onto it. The fabrics are then subjected to heat and pressure, causing the adhesive to bond the two layers together in a pattern of small dots or circles. This creates a textured effect on the surface of the fabric, which can be used to add design elements or improve the durability of the fabric. Dot lamination is commonly used in the production of outerwear or workwear, such as jackets and raincoats, to create a waterproof or water-resistant barrier.

Check: Use of Membranes

Our Waterproof & Breathable Technologies

Our waterproof technologies are methods of bonding or laminating materials together. These use heat to create a bond between two materials. However, our lamination developments differ in the specific method of application of heat and adhesive. There are a lot of variables to consider during bounding or lamination processes to obtain the requested strength and appearance.

Flamebounding

Flame lamination is a textile process used to bond two or more layers of fabric using heat and flame. In this process, a layer of foam is applied to one of the fabrics, and then the two fabrics are fed through a bounding installation that applies a controlled flame to the thermoplastic layer. The heat from the flame melts the foamlayer, causing it to bond with the other fabric. The result is a strong, durable bond between the two fabrics that is water-resistant and often used in applications such as shoe linings, sportswear, upholstery, and many more. Flame lamination is a fast and efficient process that allows for precise control of the bond strength and is often preferred over other bonding methods for its speed and accuracy.

Dotlamination

Dotlamination is a process used to bond fabrics together using heat and adhesive. In this process, a thin layer of adhesive is applied to the surface of one fabric, and then a second fabric is pressed onto it. The fabrics are then subjected to heat and pressure, causing the adhesive to bond the two layers together in a pattern of small dots or circles. This creates a textured effect on the surface of the fabric, which can be used to add design elements or improve the durability of the fabric. Dot lamination is commonly used in the production of outerwear or workwear, such as jackets and raincoats, to create a waterproof or water-resistant barrier.

Why Lamination

Improved Aesthetics

Strength

Stability

Functionality

This process provides additional functionality and versatility with fabric on one side and non-woven on the other, fabric on both sides, and many variations of fabric combinations, creating composites including foams, films, and knits. These combined composite materials will have properties and characteristics that the individual layers would not have by themselves.

One-Side Bonding

Two-Side Bonding

Image Gallery

4 - Layers

Perfect for: Shoe inner lining

3 - Layers

Perfect for: Car seat cover & furniture

2 - Layers

Perfect for: furniture

LET'S WORK TOGETHER

Do you have more questions about how lamination can help you in your product development? Our team of experts is ready to consult with you on materials, processes, applications, and custom solutions that meet your most demanding projects.